Below Zero

Read full essay

“Good, better, best. Never let it rest.

Until your good is better and your better is best.”

That Zero Harm goal on all the posters may seem insurmountable. A more fruitful path is to get to the numbers behind the number… a path to get you below zero. Let’s learn how some companies achieve Below Zero…

Your annual injury rate is a static number. It can define your safety program performance but injury rates can seem random. It’s frustrating working so hard to reduce that rate only to have it bounce around arbitrarily.

Best-in-Practice Behavioral Safety Programs

I work with the Cambridge Center for Behavioral Studies (CCBS), a not-for-profit organization whose mission it is to reduce human suffering through the application of behavioral science. Applications of behavioral science have impact on people (and animals) through work in autism and human services, in schools and prisons, attacking violence and encouraging volunteering, and, of course, increasing safe behaviors in the workplace.

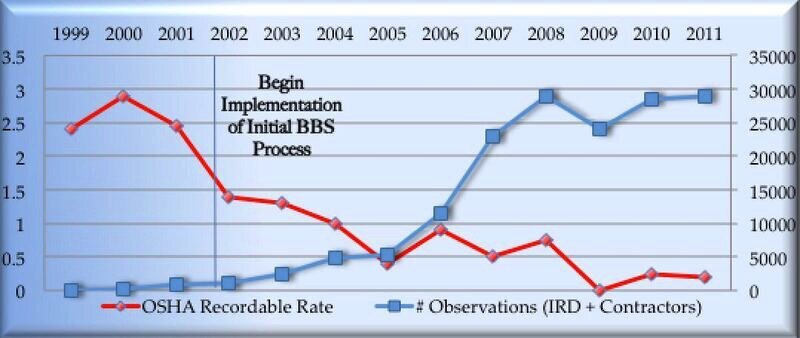

CCBS accredits the best-in-practice safety programs around the world who have had a significant reduction in injuries associated with the use of behavior science. It’s cool to visit these programs, meet amazing people, and learn what makes them great. It’s a beautiful thing to review data where injury rates are near zero and have been for many years. See for yourself - check out the injury recordable data from Eastman Chemicals Acetate Fiber Division(AFD) and Marathon Petroleum Company Illinois Refining Division(IRD) below. Feel free to go to behavior.org and check out other companies whose applications show their data and describe their behavioral safety programs in detail.

Most of these companies experienced the two S-Curves. The first drop in injuries was achieved grabbing the low-hanging fruit by implementing sound safety management systems like processes and rules, guarding and LOTO, training, safety meetings and the like. They then experienced a “plateau” and learned they needed to engage their employees to start the next S-Curve. They studied, learned about safety cultures, and ultimately adopted behavioral safety. The second S-Curve got them substantially below industry standards and near zero.

Yet statistically, the closer you get to zero the harder it gets.

Stretch a rubber band in front of you. Pretend the stretched rubber band is your industry’s average for injuries. You work hard to pull that injury rate down. Much like pulling the middle of that rubber band downward… easy at first but then it gets increasingly harder. What does that rubber band want to do? Bounce back.

Consider all the forces trying to bounce your injuries back up: aging equipment, aging workforces and new workers, cost cutting and production pressures, new leadership, etc The further you pull toward zero injuries the more pressure you’ll feel trying to force that number back up. So staying near zero is an achievement by itself. But its not very satisfying or reassuring.

How to get BELOW ZERO

Communication is the key to a positive safety culture: Peers giving feedback about risk to peers, supervisors sharing safety tips with their team, managers looking at data and asking questions. The more everyone talks about safety the better.

One type of communication that is critical to reducing injuries is when employees communicate where hazards are, what risks are being taken, and when they have a close call or minor injuries.

Reporting is a behavior we can promote among our employees. Reporting helps us discover where injuries lurk. Reporting allows us to intervene proactively to make the workplace safer before injuries happen. Reporting is a measure of communication and a really good one.

Every CCBS accredited site measures reporting. It’s easy to see the relationship between increases in reporting and decreases in injuries.

Marathon Petroleum’s Illinois Refining Division’s reporting increased in the number of behavioral safety observations turned in by their staff and contractor workforce.

Eastman Chemical’s Acetate Fiber Division’s reporting increased two ways. The number of at-risk behaviors reported by their workforce in their behavioral safety program increased as did their near-miss reports in the same time period.

To better understand the relationship between reporting and injuries let's flip em.

Take these same graphs and turn the reporting data upside down. Now increases in reporting instead trend downward from zero.

Notice that injuries tend to decrease as if pulled down by reporting.

Injuries cannot go below zero and its rare and improbable to achieve zero injuries. But you can achieve Below Zero with a strong reporting culture helping you fight the forces trying to increase your injury rate. More reporting allows you to proactively mitigate hazards and risks catching these forces in the act, before they injure.

Instead of trying to hold that rubber band down all by yourself,

reporting allows ALL of your employees to pull that rubber band down BELOW ZERO!

Would you like to hold down that rubber band by yourself

or have your whole workforce helping?